TCVJ

THOMPSON CONSTANT VELOCITY JOINT

Power Without Compromise: Thompson TCVJ® Constant-Velocity Joints

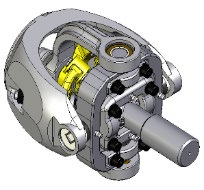

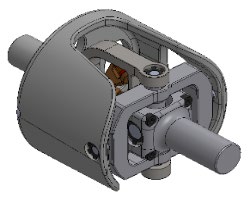

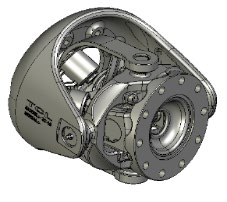

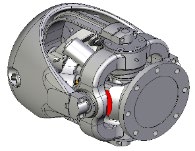

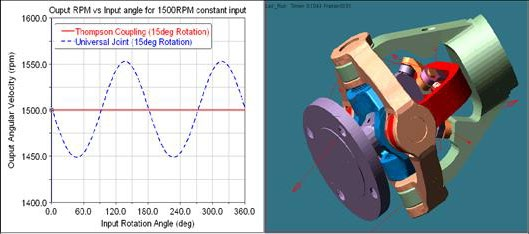

The Thompson Constant Velocity Joint (TCVJ®) rewrites the rules of driveline design, delivering true one-to-one shaft speed through large articulation angles while running cool, quiet, and virtually vibration-free. By eliminating the sliding interfaces found in traditional CV and universal joints, the Australian-engineered TCVJ® slashes energy losses and maintenance costs—making it the first choice for marine propulsion, monorail traction, heavy agriculture, and high-precision industrial machinery.

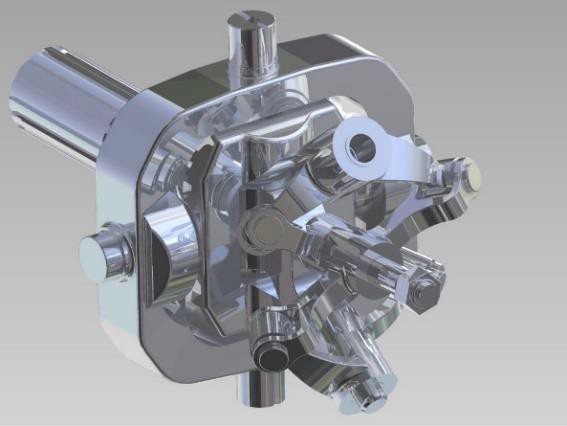

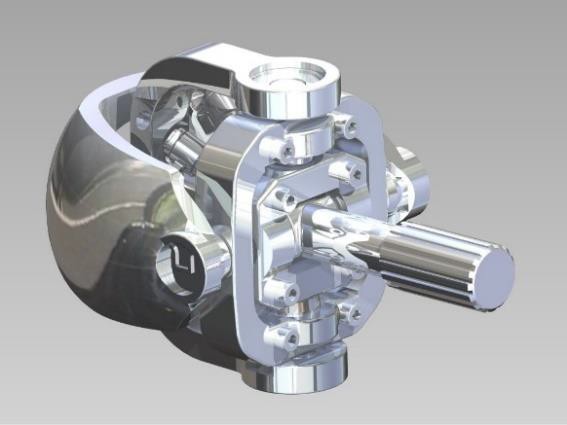

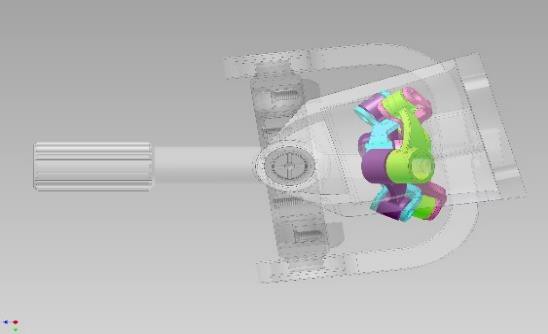

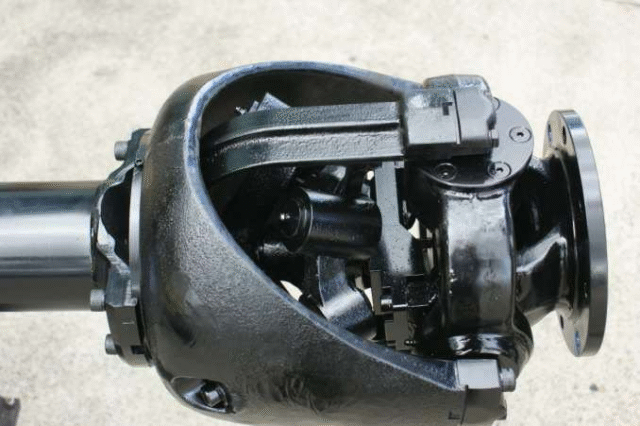

How the TCVJ® Works

-

Runs at near-ambient temperatures even under full load.

-

Maintains >99.95% mechanical efficiency across rated speeds and angles.

-

Exhibits negligible backlash, ensuring smooth load reversals in servo-critical systems.

-

Wide-Angle Capability – Standard units operate continuously to 15°; specials reach 30° and prototypes up to 45° without speed derating.

-

High Torque Density – Nominal ratings to 6,350 Nm with peak capacities to 20,000 Nm in the compact TCVJ-8000-10 size.

-

Maintenance-Free Construction – Sealed bearings, no load-bearing sliding surfaces, and fully greased internals deliver multi-year L10 life with zero re-lubrication.

-

Energy Savings – Independent tests show power-loss reductions of up to 10% versus elastomeric and conventional CV couplings when misaligned.

|

Model

|

Nominal Torque [Nm]

|

Max Torque [Nm]

|

Max Speed [rpm]

|

Full Angle [°]

|

Swing Ø [mm]

|

Length [mm]

|

Weight [kg]

|

|---|---|---|---|---|---|---|---|

|

TCVJ-50-30

|

50

|

200

|

3,000

|

30

|

75

|

68

|

1.0

|

|

TCVJ-500-15

|

500

|

1,200

|

3,000

|

15

|

193

|

169

|

11.0

|

|

TCVJ-2000-15

|

2,000

|

7,700

|

2,500

|

15

|

260

|

225

|

22.0

|

|

TCVJ-5000-15

|

5,000

|

13,600

|

2,000

|

15

|

393

|

347

|

82.5

|

|

TCVJ-8000-10

|

6,350

|

20,000

|

1,600

|

±10

|

350

|

394

|

80.7

|

All models achieve >99.95% efficiency and withstand continuous service temperatures to 120 °C.

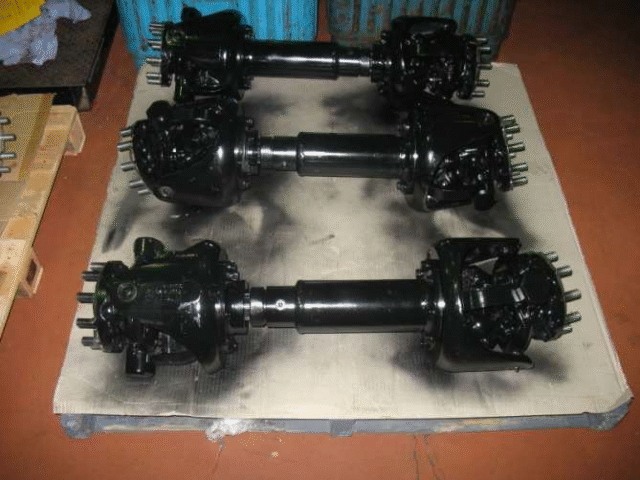

Real-World Success Stories

A Queensland ferry fleet installed twin TCVJ-2000-15 joints between diesel engines and waterjets. After 18 months of round-the-clock operation, bearing temperatures remain within 5 °C of seawater ambient and vibration levels dropped by 40% versus the original cardan shafts.

A 32 m sport-fisher incorporated a single TCVJ-8000-10 to offset its propeller shaft by 10°, freeing critical engine-room space. Sea trials confirmed imperceptible driveline vibration and reduced hull-borne noise by 3 dB(A), enhancing passenger comfort.

-

Flange or Shaft Ends – Custom ISO-pattern flanges or splined stubs for drop-in replacement of cardan, Rzeppa, or elastomeric couplings.

-

Modular Slip-Shafts – Optional sliding spacers accommodate axial float and facilitate fast gearbox removal in process plants.

-

Corrosion-Resistant Builds – 316 SS and duplex options for offshore or caustic environments, with ATEX certification on request.

-

True Constant Velocity for precision processes.

-

High Angle + High Torque capability unmatched by other CV technologies.

-

Proven Field Reliability across marine, transport, industrial, and agricultural sectors.

-

Sealed-for-Life Convenience—install once, forget for years.