Alignment Eliminator Couplings

Revolutionising Shaft Couplings: The TCAE™ Alignment-Eliminator

Eliminate alignment headaches, slash maintenance costs, and protect critical rotating equipment with the patented TCAE™ “Alignment-Eliminator” couplings from Thompson Couplings.

Transformative “Fit-and-Forget” Design

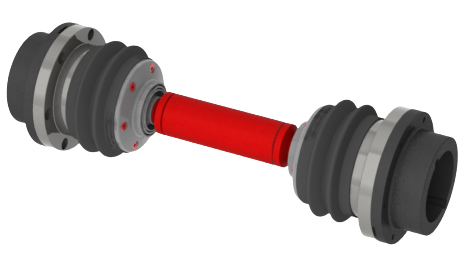

Traditional shaft couplings demand painstaking laser alignment and ongoing maintenance to prevent premature wear, downtime, and energy waste. The TCAE™ range replaces this burden with a unique double-hinged mechanism that:

-

-

Handles up to 10° combined misalignment (angular, parallel, axial) without inducing harmful side-loads on bearings or seals.

-

Eliminates the need for laser alignment, enabling dynamic self-adjustment under thermal growth, shock loads, vibration, and soft-foot conditions.

-

Completely sealed-for-life, requiring only occasional wash-down cleaning and no lubrication for its entire service life.

-

Key Benefits

-

Reduced Total Cost of Ownership

- No alignment services or lubrication costs.

-

Extended machine life by minimizing side-loads on pumps, motors, and gearboxes.

-

Energy savings of up to 10% under misalignment conditions compared to standard elastomeric couplings.

-

Quick, Intuitive Installation

-

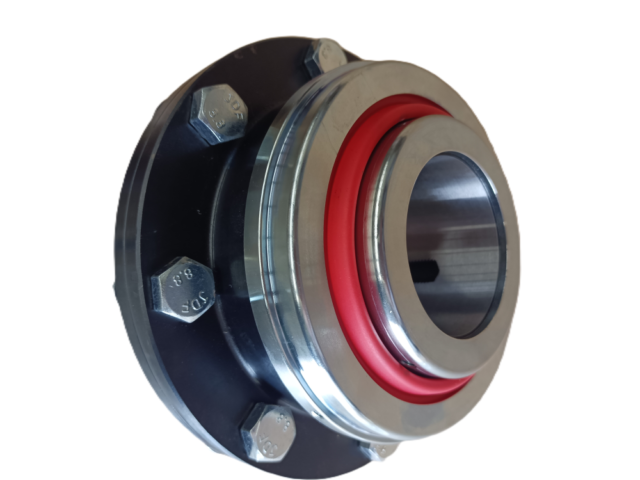

Quick-release flanges slide onto shafts and lock into place.

-

TCAE™ compresses and expands to fit DBSE (Distance Between Shaft Ends) in seconds.

-

Ready-to-operate immediately—laser-alignment only for initial placement.

-

-

Unmatched Reliability in Harsh Environments

-

Sealed-for-life stainless internal components withstand wash-down, corrosion, and explosive atmospheres (ATEX).

-

Ideal for remote or hazardous installations (mine-site water-feed pumps, marine drives, oil & gas rigs) where routine alignment is impractical or dangerous.

-

-

Versatile Series Selection

-

S-Series: Compact standard DBSE, torque ratings from 14 to 12,217 Nm at speeds up to 3,000 rpm.

-

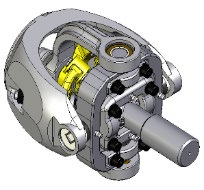

V-Series: Vertical-mount capable, high-torque pumps up to 5,573 Nm with ±10° misalignment tolerance.

-

R-Series: True constant-velocity for precision drives, mid-range speeds to 3,000 rpm, torque up to 316 Nm.

-

L-Series: Spacer couplings for long-span DBSE (10–600 mm), torque up to 591 Nm, hollow and solid shaft options for engine-dyno and genset applications.

-

Real-World Impact: Case Studies

Papermill Retrofit Replacing universal joints with a TCAE-L-7 coupling at an Indonesian facility eliminated quarterly failures, reduced downtime by 90%, and delivered maintenance-free operation for over eight years.

Pump-Motor Drives A 0.75 kW motor coupled with a TCAE-R-2 exhibited negligible power penalty even at 5° offset, versus 10% energy loss on a competing elastomeric design—translating to ROI within months.

Vertical Deep-Well Pumps In corrosive wash-down environments, the V-Series maintained seal integrity and torque transmission without lubrication, extending service intervals from months to years.

Why Choose TCAE™?

By removing the alignment step and allowing dynamic compensation for real-world operating conditions, TCAE™ couplings deliver:

-

Immediate cost savings: Fewer service interventions, reduced energy consumption, and minimal spare-parts inventory.

-

Enhanced uptime: “Set-and-forget” reliability even under thermal expansion, soft foot, or foundation shifts.

-

Flexibility: Broad series coverage for virtually any torque, speed, or DBSE requirement.

Upgrade your driveline strategy with Thompson Couplings’ TCAE™ Alignment-Eliminator. Contact us for sizing guidance, CAD models, and custom-length spacer options—and experience the truly “fit-and-forget” coupling solution.